EZstrip™ Transfer Pump

For the newest iteration of our EZstrip™ maintain-in-place progressing cavity pump we designed new features to make maintenance even more user friendly than before. In addition to our patented split suction chamber we’ve removed the tie bars, designed a new positive torque split coupling rod, and added in a captive support foot. That means faster, easier maintenance for you. The EZstrip has been specifically designed to provide a quick and easy way to disassemble, de-rag and maintain a PC pump in-situ, eliminating the costly maintenance and down time that servicing can often cause.

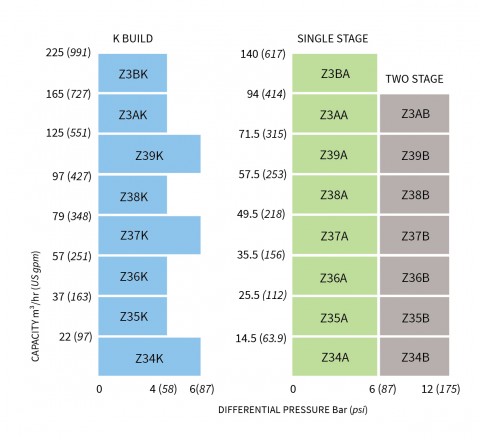

| Capacity | Pressure | Temperature | Notes | |||

|---|---|---|---|---|---|---|

| m³/h | 225 | bar | 12 | °C | -10 up to 100 | (for higher temperatures please contact us) |

| gpm | 990 | psi | 175 | °F | 14 up to 212 | |

Applications

| Domestic sewage | Industrial effluents |

| Hydrated lime slurry | Sludge |

| Shear sensitive latex emulsion | Milk curds |

| Sauces | Fruit juices |

| Industrial chemicals and detergents | Starch slurries |

| Coating clays | Gypsum |

| Silicate | Paper stocks |

| Agricultural slurries |

Features & Benefits

Maintain-in-Place

Quickly and safely remove the full drive train including rotor, stator, shaft, rod, and seal in minutes without physical electrical disconnection.

EZstrip Access covers– provide 360° access to coupling rod and drive shaft for easy inspection.

The smooth profile Positive Torque Split Coupling Rod alleviates potential ragging issues, and reduces maintenance and assembly times.

Tie-bar-free design. EZstator clamps lock the stator securely into place. This further reduces stator removal time by over 50% and improves the safety of common maintenance operations.

Captive support foot. The fixed support foot and stator clamp assembly further aids rotor and stator removal.

Materials of Construction

Available in cast iron or stainless steel with a choice of rotor and stator materials to suit individual applications.

No Special Tools Required

Pump requires only a wrench and an allen key to maintain.

No De-Rating Required

Operational parameters unaffected since design has no effect on flow and pressure.

Eliminate Dismantling Lengths

Suction and discharge ports remain connected to the pipe work. Easily upgrade from any model PC pump, or retrofit an existing EZstrip™ pump model.

Interchangeability

Compatible with new pumps or retrofitted into existing Compact C and B-Range installations.

Drive Train Assembly

Pre-assembled drive trains available to support faster reassembly times.

EZstrip De-Rag Video (commentary available if you have speakers)

Sorry, flash is not available.

EZstrip Disassembly Video (commentary available if you have speakers)

Sorry, flash is not available.

EZstrip Assemble Video (commentary available if you have speakers)

Sorry, flash is not available.