Products

Series A Muncher

Series A Muncher

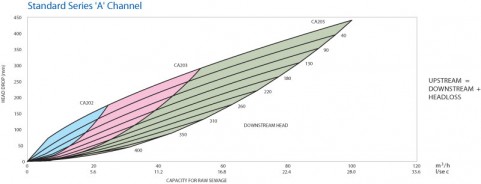

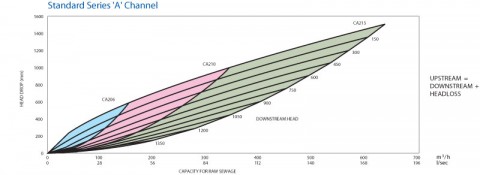

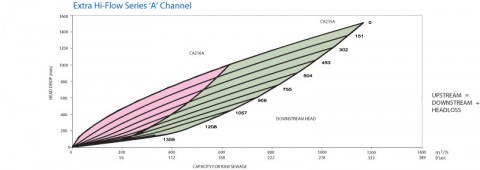

The reliable Series 'A' Muncher® is well proven in its ability to effectively macerate raw sewage, sludges, sewage screenings and industrial process flows. Available for pipeline or channel installations, the shaft speed of 85 rpm offers low cutter tip speeds and therefore dramatically reduces wear rates in comparison to high speed macerators.

The Series 'A' Muncher can be packaged with a Monoflo pump or screen to provide a highly effective macerating, screening or pumping system.

| Capacity | |

|---|---|

| m³/h | Up to 1,400 |

| gpm | Up to 6,164 |

Applications

| Protection of pumps to eliminate blockages | Submersible pump protection |

| Fine grinding of sewage and sludges | Disintegration of extracted screenings |

| Head of works maceration | Industrial effluent maceration |

| Mud contaminated drill cuttings | Food products and waste |

| Slaughterhouse waste | Aircraft effluent |

| Prison waste water maceration |

Features & Benefits

- Power savings, elimination of manual handling and associated transport costs, odour control and automated operation are all achieved when installing Munchers to replace conventional screening systems to existing or proposed submersible pump stations

- Monoflo ETOS cutters offer positive and effective solids grinding

- Optional high flow side rails allow higher capacities whilst reducing the possibility of solids passing through without being macerated – typically an increase in capacity of 40%

- Can be installed in an existing concrete channel or in a fabricated frame, complete with guide rails, into existing submersible pump stations as a simple and quick retrofit

- Each Muncher is supplied with a programmable logic controller (PLC) to protect the machine against damage and overloads

- Muncher can be supplied to comply with the ATEX Directive 94/9/EC